Total solution for QFN / DFN Side-Wettable Flanks

The use of leadless packages grows rapidly due to increasing component density. QFN/DFN packages have the disadvantage that the solder connection can only be inspected using x-ray processes, rather than Automated Optical Inspection (AOI). For the Automotive industry the AOI option is essential.

Besi introduces together with chemical partner Sytron a complete solution to ensure AOI is possible for QFN/DFN packages.

Processing ensures:

-

Immersion Tin plating (autocatalytic process) on full QFN/DFN Cu surface.

-

100% solderability pass after 16hr dry bake.

-

100% solderability pass after 8hr steam aging.

-

No exposed Cu areas.

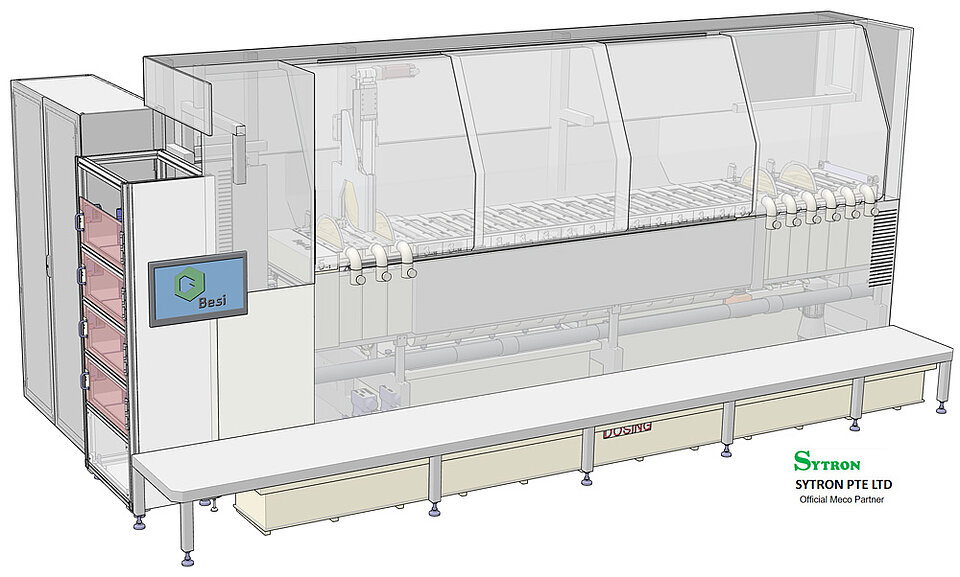

Equipment:

-

Handling of Tape Ring with singulated QFN / DFN packages (8” / 10” / 12”).

-

20 Tape Rings per hour.

Excellent solderability on full Cu surface |

|

| 16 hours bake @ 150oC | 8 hours steam aging |

|

|

|

|

|

|

Whitepaper Wettable Flank

Meco has written a whitepaper with more information about Wettable Flank. Download it below.

Meco Wettable Flank Plating

Meco has a full solution for your wettable flank products, with the new Meco WFL-20. The Meco WFL-20 is the highly advanced solution for your wettable flank surface mount. Download the product flyer below.

Meco Equipment Engineers B.V.

Tel: +31 416 384 384

Het Sterrenbeeld 24

5215 ML 's-Hertogenbosch

The Netherlands