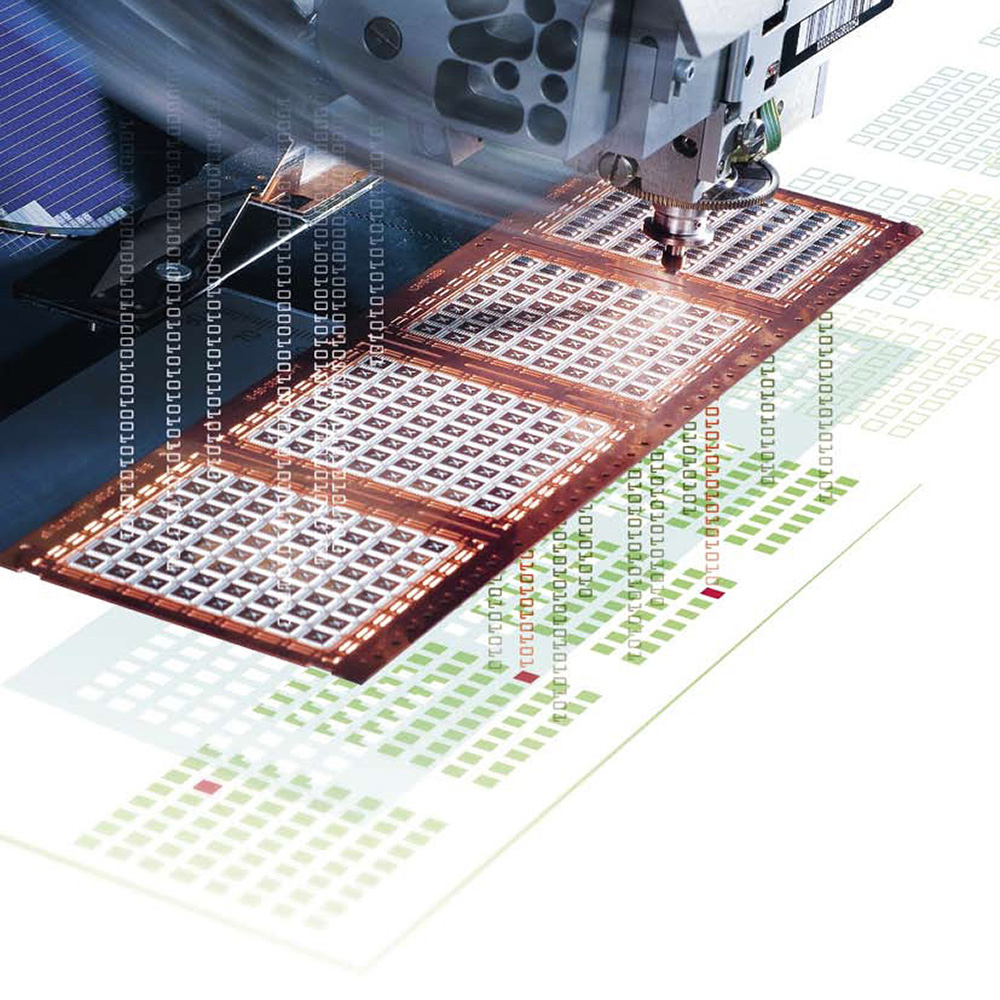

Die Bonding

In back-end semiconductor manufacturing, the die attach process is a critical step. At first glance, die attach seems to be a simple process step in the semiconductor manufacturing chain. However, the continuously increasing requirements of today's applications set high standards in die bonding. Besi’s die attach equipment is based on unique and innovative concepts offering economical benefits to customers.

Esec 2100 hS ix

The Esec 2100 hS ix is the latest member of the 2100 i Die Bonder family. It is optimized for highest speed and scratch-free transport thanks to the easy-to-use motorized and programmable rail strip handler.

Esec 2100 sD advanced i

The new Esec 2100 sD advanced i with its new Device Height Sensor and High Precision Bond Head enables unmatched process capability also including High BLT applications.

Esec 2100 hSi

The new Esec 2100 hSi with its new Dual Dispensing Module enables an unmatched productivity and process quality.

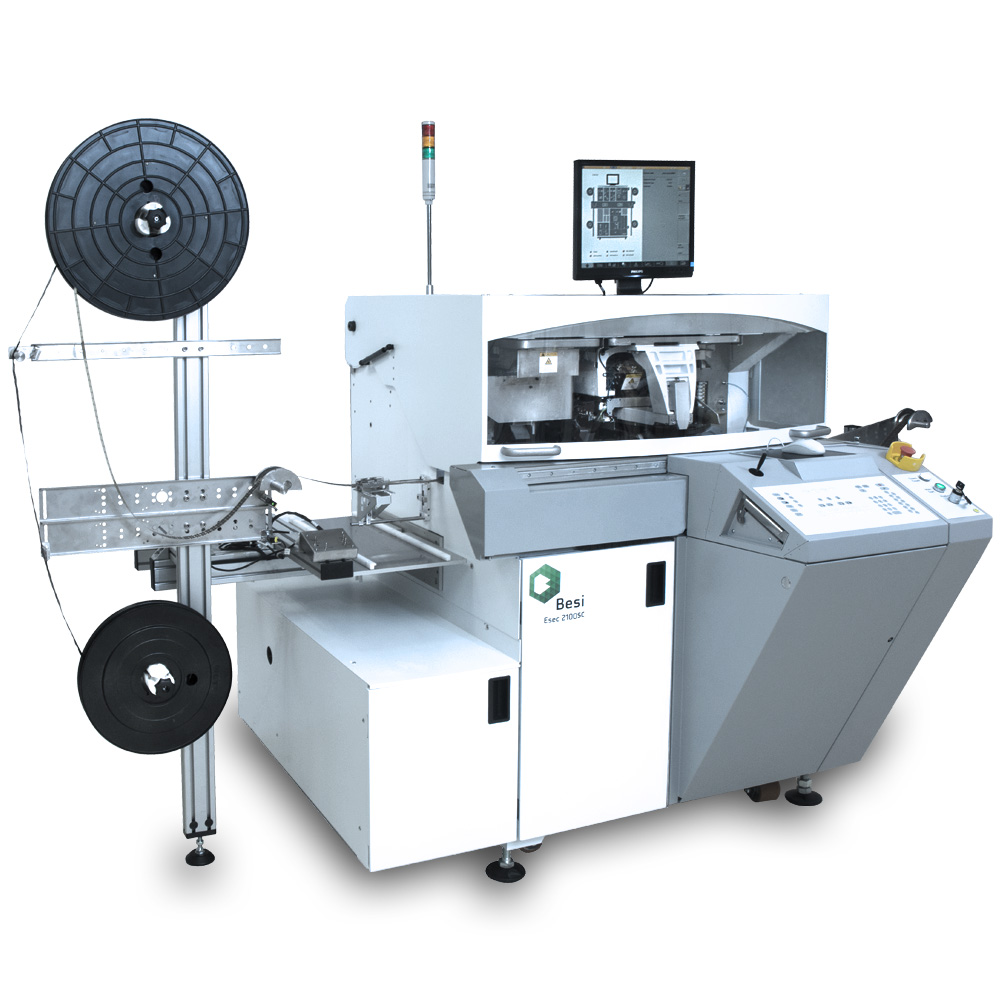

Esec 2100 hS

The Die Bonder Esec 2100 hS is the 3rd generation of the most flexible 300 mm high speed platform, capable of running an extensive range of epoxy die attach applications.

Contact

Besi Netherlands B.V.

Tel: +31 26 319 6100

Besi Switzerland AG

Tel: +41 41 749 5111

Besi Austria GmbH

Tel: +43 5337 6000

Meco Equipment Engineers B.V.

Tel: +31 416 384 384