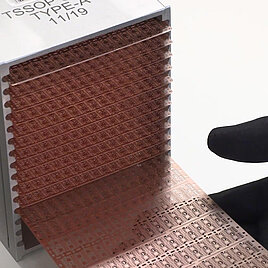

MMS-X

The MMS-X is the manual version of the AMS-X. Like the automatic system, it uses a newly developed plate press.

The extremely compact and rigid construction allows you to obtain a perfect and bleed free end product. The press has 4 individually controlled clamp modules that ensure a high and even clamp force all around the product.

Low cost product development

The MMS-X is perfectly suited for molding process parameter optimization, small production batches or offline mold cleaning. It is ideal for low cost product development and to determine the process window for your product. Optimized parameters can easily be copied to the AMS-X, automatic molding system, for large scale production. Original Besi molds can be used on both the MMS-X and AMS-X.

User friendly

With its new UX-design, the MMS-X is the most user friendly manual molding system ever. It allows you to seamlessly switch over to an automatic system without any kind of long learning curve. Intuitive, easy and fast.

More information

Seeing is believing, so we are more than happy to give you a demonstration on a live system. Contact us today for more information.

Key features

MMS-X

- Flash free - patented clamping mechanism

- High quality molding - full process control, dynamic clamping

- Low compound usage - unique runner design

- Suited for High Density and Power products

- For process development and small production batches

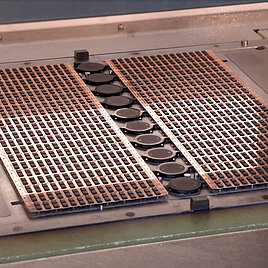

Strip molding

- Strip size up to 125 x 300 x 10 mm

- Power - IGBT - MEMS - QFN - QFP - SOT

- Focus on automotive market

Molding Press

- High clamp force

- Recipe controlled deep vacuum level

- Individually controlled 4-section clamp cylinders (optimal and equal substrate clamping)

- Even mold cap planarity

User friendly

- New UX-design - guided operation

- Intuitive touch screen operation

- Maintenance friendly

- Easy and fast mold exchange

- Easy installation

Cavity vacuum

- Void free end product

Compatible

- Fully compatible automatic and manual system

- Interchangeable molds

- Process parameter exchange

- Universal parts

Specifications

Machine Dimensions*

| Width | 1,292 mm |

|---|---|

| Depth | 1,500 mm |

| Height | 1,860 mm |

| Weight | Approx. 2,600 kg |

* Base dimensions of the system, without protrusions like exhaust, hand grips and HMI support.

Leadframe Dimensions

| Width | Max. 125 mm |

|---|---|

| Length | Max. 300 mm |

| Thickness | Max. 10 mm |

Supply Requirements

| Voltage | 208-230-380-400-440-460-480VAC - 3~ |

|---|---|

| Frequency | 50 / 60 Hz |

| Power consumption | 6 kVA |

| Compressed air | 4.5 - 9 bar |

| Average air consumption | 5 m3/h at 6 bar |

| Factory exhaust | 500 m3/h |

Press and Mold Properties

| Max. clamp force | 1,800 kN (180 ton) |

|---|---|

| Max. mold opening | 150 mm |

| Max. transfer pressure | 15 MPa (150 bar) |

| Pellet diameter | 14, 14.3, 16 or 18 mm |

| Max. number of plungers | 12 |

| Max. cavity temperature difference | ± 2 ºC |