Fico Molding Line

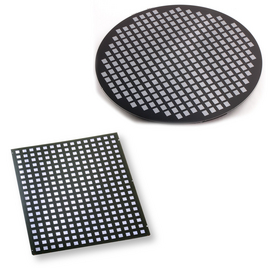

The new Fico Molding Line (FML) is a transfer molding system for wafers and large panels. It can mold wafers of up to 12" (305mm) and panels up to 300x340mm. The Fico Molding Line can mold both overmolded and exposed die products in the same mold configuration, something that is not possible with compression molding.

100µm cap height

The FML uses a conventional transfer molding concept to overmold products. With the standard top foil addition it can also perfectly mold exposed die products. Fill heights, as low as 100µm, and small gaps between dies, as low as 50µm, can be achieved. Despite the small cap height and the large molding surface, the end product remains free from voids, flash or bleed. Even extreme low vicosity compounds are no problem for the FML, the end product will be perfect of quality, outperforming liquid or powder compression molding. Advanced handling capabilities, a high precision mold with several vacuum systems allow also trouble free production of molded underfill products.

Substrates, glass and silicon

The Fico Molding Line is able to mold substrates, standard silicon and glass wafers. With its advanced clamp force and level control, it can also handle extreme thin and sensitive stacked wafers.

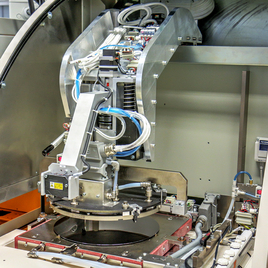

Manual and automatic system

The Fico Molding Line is already available as a manual system for product development. An automatic system is being optimized and in beta test at several customer sites. It will be released later. With the new modular FML design, a manual system can be upgraded to an automatic system when production ramps up.

Also read the article on Exposed die fan-out wafer-level packaging by transfer molding in Chip Scale Review.

Key Features

Wafers and panels

- Wafer diameter up to 305 mm (>12”)

- Panel size up to 300 x 340 mm

- Low cap size, down to 100 µm

- Small channels between dies / packages

Foil molding

- Exposed die molding for Flip Chip & Wafer packaging (only possible with transfer molding)

- Bleed free molding, without post processing (no back grinding needed)

- No mold cleaning necessary

Easy operation

- Fast tool exchange

- Easy accessible machine

- Touch screen interface

- Intuitive interface

- Built in hand exhaust

Molding press

- Top edge injection transfer molding

- Standard pellet material handling

- Dynamic clamping control, protects from die and wafer crack (very flexible clamp control, multiple clamp force profiles possible)

- Active clamp force level control for precise mold cap height and planarity

- New dynamic transfer pressure control, optimized transfer profile to ensure exact repeatable process conditions

- Mold integrated degating

- Accurate multi zone temperature control

- Board, cavity and foil vacuum

- Glass wafer handling

- Silicon wafer handling

- 17 process patents

Standard building blocks

- Modular building blocks for wafers and panels

- Fully compatible automatic and manual systems

- Tools and process parameters fully exchangeable

- Universal parts (low spare stock)

- Common modules (FML-FCL-FSL)

Vacuum

- Supreme board and wafer vacuum

- Cavity vacuum control

- Void free end product

- Suited for complex molded underfill (MUF and eMUF) packages

- Suited for ultra low packaging and micro SIP sealing

Specifications

Machine Dimensions

| Width | 1.528 mm |

|---|---|

| Depth | 1,800 mm |

| Height | 1,800 mm |

| Weight | Approx. 2,740 kg |

Wafer Dimensions

| Diameter | 200 - 305 mm (8" to 12" wafers) |

|---|---|

| Thickness | 0.6 - 1.2 mm wafer thickness (stacked wafer thickness down to 50µm) |

| Package height | Max. 1.5 mm (depending on configuration) |

Panel Dimensions

| Width | 200 - 305 mm |

|---|---|

| Length | 200 - 340 mm |

| Thickness | 0.1 - 1.5 mm |

| Package height | max. 1.5 mm (depending on configuration) |

Supply Requirements

| Voltage | 208-230-380-400-440-460-480VAC - 3~ |

|---|---|

| Frequency | 50 / 60 Hz |

| Power rating | 5.5 kVA |

| Compressed air | 5 - 10 bar |

| Average air consumption | 1.5 m3/h at 6 bar |

| Factory exhaust | 100 m3/h @ 150 mm |

| Connection | Top or bottom supply |

Press and Mold Properties

| Max. clamp force | 1,200 kN |

|---|---|

| Max. mold opening | 90 mm |

| Max. transfer pressure | 180 bar |

| Pellet diameter | 14 - 18 mm |

| Number of plungers | 2 or 4 |

| Max. pellet stack length | 120 mm |

| Max. cavity temperature difference | ± 3 ºC |

| Accoustic noise | < 73 dB(A) |

| Max. speed | 10 carriers per hour per press |