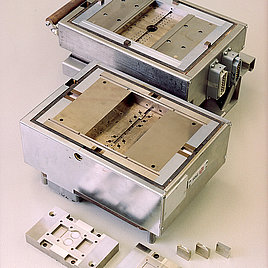

Fico MMS-i

The Fico MMS-i is a single press, manual version of the Fico AMS-i automatic molding system. It was especially developed for molding process parameter optimization. By making use of test molds, new products can be developed and optimized prior to large scale production. Besides that, the Fico MMS-i can be used for small production batches or offline cleaning of the molds that are used in the Fico AMS-i.

User friendly

The user friendliness of the Fico MMS-i creates the opportunity to quickly introduce new products by making use of test molds. As on the automatic version, several optional systems can be used on the Fico MMS-i, to even enhance the field of use.

More information?

Curious of what the Fico MMS-i can do for you? Contact the Besi sales department for more information.

Key Features

- 90 ton press station

- Cavity vacuum

- Hand vacuum cleaner

- Automatic tool ID

- Multi voltage input transformer

- Ergonomic design

Specifications

Machine Dimensions

| Width | 1,210 mm |

|---|---|

| Depth | 858 mm |

| Height | 2,004 mm |

| Weight | Approx. 1,400 kg |

Leadframe Dimensions

| Width | Max. 75 mm |

|---|---|

| Length | Max. 280 mm |

Supply requirements

| Voltage | 208-230-380-400-440-460-480VAC - 3~ |

|---|---|

| Frequency | 50 / 60 Hz |

| Power rating | 78.5 kVA |

| Compressed air | 5 - 10 bar |

| Average air consumption | 1.5 m3/h at 6 bar |

| Factory exhaust | 600 m3/h at 50 Hz |

Press and mold properties

| Max. clamp force | 900 kN |

|---|---|

| Max. mold opening | 124 mm |

| Max. transfer pressure | 120 bar |

| Pellet diameter | 11, 14 or 14.3 mm |

| Max. number of plungers | 10 |

| Max. cavity temperature difference | ±2ºC |

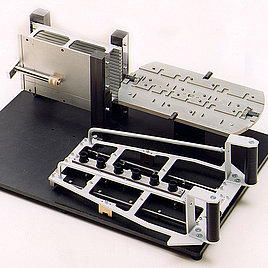

Options

- Board vacuum

- Final transfer pressure control

- Manual foil handling

- Mold transport carrier

- Mold preheat station

- Manual pellet loader

- Manual pellet and leadframe loader