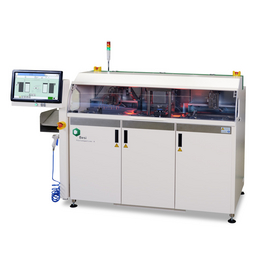

Fico Compact Line - X

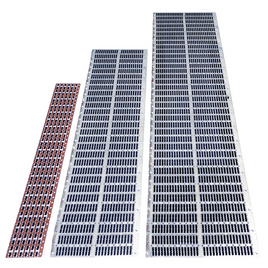

The new Fico Compact Line - X (FCL-X) is the latest development in Trimming & Forming and can process extreme high density leadframes up to 125 x 300 mm. The FCL-X is the answer to the increasing accuracy and Cpk demands.

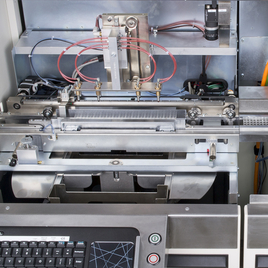

Increased press force

The FCL-X press has an increased press force to process extreme high density leadframes. Its advanced pollution control system allows trouble free processing of preplated and interdigit leadframes. Each press has dedicated aspiration, with controlled high air flow speeds and a unique cyclone dust filter.

Different loaders and offloaders

A range of loader and offloader modules are available, ranging from magazines and cassettes to tray, bulk and tube. Short and controlled transport distances increase the performance of the FCL-X and at the same time prevent damage to your products.

More information?

Every FCL-X configuration is adapted to your product. Curious of what the FCL-X can do for you? Contact the Besi sales department for more information.

Key Features

Wide range of available modules

- Dual Stack Magazine Handler

- Control Unit

- Slotted Magazine Loader

- Press Module

- Bulk Offloader

- Laser Marker

- Separator to Sorter

- Device Sorter

Dual Stack Magazine Handler

- Loader or offloader use

- Dual stack with automatic magazine rotation

- Auto ejection of rejected leadframes

- Servo motor controlled leadframe pusher

- Strip loading with vacuum pick-up head (ESD safe)

- Very short leadframe travel

- Smooth leadframe accelleration and transport

- Closed magazine bottom handling (option)

Vision Inspection

- Leadframe identification

- Leadframe orientation

- Bottom and/or Top inspection

- Large field of view

- High definition camera

- Stable construction

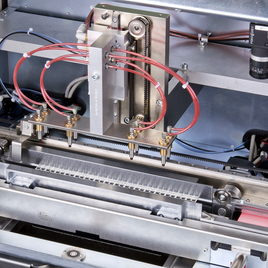

Press

- High press force: 50 kN (6.6 Joule)

- Optical contactless safety pin detection

- High airflow (vacuum and/or compressed air) in tool

- Exhaust system per press

- Easy tool exchange

- RFID tool recognition

- Output control from user interface

Tool

- High accuracy and reliability

- Sophisticated design for easy maintenance

- Different forming principles

- 125 mm tool width

- Enhanced pollution conttrol

Bulk Offloader (Binning)

- 4 bins (configurable function)

- Three 1 liter bins, one small reject bin

- Product offloading directly down from tool

- Short distance – no sticking

- Vacuum in tool through bin for controlled product flow

- Easy bin exchange – software controlled

Control unit

- Large 550mm touch screen user interface

- Customizable warning & status light

- Built in illumination

- Hand exhaust (option)

- SECS/GEM (option)

Slotted Magazine Loader

- Large 600mm cassette buffer

- Automatic magazine/leadframe centering

- Ionizer (option)

Specifications

Machine Dimensions

| Width | depends on the configuration |

|---|---|

| Depth | 950 mm |

| Height | 1,455 mm |

| Weight | depends on the configuration |

Product Handling Specifications

| Leadframe length | 170 - 300 mm |

|---|---|

| Leadframe width | 18 - 125 mm |

| Leadframe thickness | 0.1 - 0.4 mm |

| Package thickness | 0 - 5 mm |

Supply Requirements

| Voltage | 208-230-380-400-440-460-480VAC - 3~ |

|---|---|

| Frequency | 50 / 60 Hz |

| Power rating | depending on the configuration |

| Compressed air | 5 - 10 bar |

| Air consumption | dending on the configuration |

Speed and Noise level

| Speed | Max. 250 strokes per minute |

|---|---|

| Noise level | Lower than 73 db(A) |

Available modules

| DSMH | Dual Stack Magazine Handler |

|---|---|

| CU | Control Unit |

| SML | Slotted Magazine Loader |

| PM | Press Module |

| BO | Bulk Offloader |

| LM | Laser Marker |

| S2S | Separator to Sorter |

| DS | Device Sorter |

Dual Stack Magazine Handler

| Magazine height | 150 - 600 mm |

|---|---|

| Magazine length | 150 - 306 mm |

| Magazine width | 25 - 131 mm |

| Magazine weight | max. 15 kg (including leadframes) |

Slotted Magazine Loader

| Magazine height | 100 - 240 mm |

|---|---|

| Magazine length | 170 - 300 mm |

| Magazine width | 25 - 160 mm |

Press Module

| Press force | 50 kN (6.6 Joule) |

|---|---|

| Tool width | 125 mm |

Downloads

PDF - 2 MB