Fico AMS-LM Top Foil

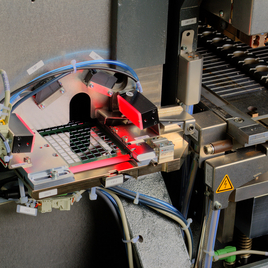

In line with the market trend of larger substrates, Besi Netherlands has introduced a new large substrate molding machine with Top Foil functionality, to mold single sided MAP products like BGA, QFN and BOC. The unique Top Foil feature on this machine allows bleed free production of bare die products.

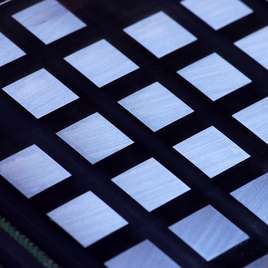

Top Foil

A special foil, guided over the top mold, creates a soft sealing layer between mold and products. As a result, the die stays clear of compound. The use of top foil eliminates an extra cleaning process step after molding. The Fico AMS-LM Top Foil can handle substrates of up to 102 x 280 mm and can handle all current single sided packages.

More information?

Curious of what the Fico AMS-LM with Top Foil can do for you? Contact the Besi sales department for more information.

Key Features

Cassette Handler

- High capacity

- Freely accessible

- Slot to slot copy

- Two or four deck version

- Bar code and RFID reader (optional)

Vision

- Leadframe orientation check

- Mark inspection

- Optical Character Verification (OCV)

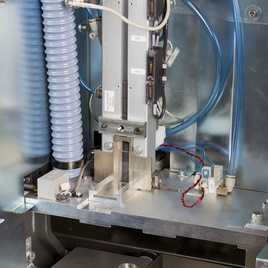

Leadframe Handler

- Automatic orientation correction

- Leadframe pre-heating

- Anti warpage leadframe cooling

- Air cushion transport

Molding Press

- Large substrate molding

- Top Foil

- Topedge molding (low viscosity compounds)

- Adjustable high clamping force

- Dynamic Clamping Control (Flip Chip Bare Die)

- 17 process patents

- Board and cavity vacuum

- Individual, equal board clamping

Pellet Supply

- Remote pellet feed (up to 40m)

- Pellet length check

- Pellet cooling

- Pellet age control

Specifications

Machine Dimensions

| Width | 3,145 mm |

|---|---|

| Depth | 1,652 mm |

| Height | 1,976 mm |

| Weight | Approx. 3,450 kg |

Leadframe Dimensions

| Width | 72 -102 mm |

|---|---|

| Length | 100 - 280 mm |

| Thickness | 0.1 - 1.5 mm |

| Height | max. 2 mm |

Cassette Dimensions

| Width | 80 - 120 mm |

|---|---|

| Length | 180 - 300 mm |

| Height | 100 - 165 mm |

| Storage capacity | 800 mm |

Supply Requirements

| Voltage | 208-230-380-400-440-460-480VAC - 3~ |

|---|---|

| Frequency | 50 / 60 Hz |

| Power rating | 9 kVA |

| Compressed air | 5 - 10 bar |

| Average air consumption | 6 m3/h at 6 bar |

| Factory exhaust | 1000 m3/h at 50 Hz |

Equipment Performance

| Uptime | ≥ 98% |

|---|---|

| Max. throughput | ca. 250 Lf/h |

| MTBF | ≥ 200 h for every MTTR of 1 h |

| MTBA | ≥ 3 h |

| MTTR | ≤ 1 h |

| MTTA | ≤ 3 min |

Press and Mold Properties

| Max. clamp force | 600 kN |

|---|---|

| Max. mold opening | 90 mm |

| Max. transfer pressure | 180 bar |

| Pellet diameter | 11, 14 or 14.3 mm |

| Max. number of plungers | 10 |

| Max. cavity temperature difference | ± 2 ºC |

Downloads

PDF - 3 MB