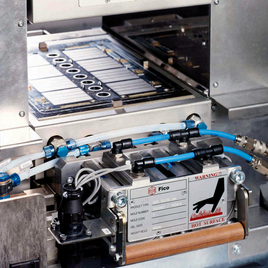

Fico AMS-i

The Fico AMS-i is a fully automatic molding system. It is designed for all current and future package types, using any type of pelletized molding compound. Independent, flexible press operation, high reliability and the shortest machine time in the market, guarantee high output. The flexible design allows easy incorporation of your specific requirements. Intelligent mold identification, which automatically loads process parameters, ensures quick start-up and ease of operation.

More information?

Curious of what the Fico AMS-i can do for you? Contact the Besi sales department for more information.

Key Features

- Product lot tracking

- Leadframe orientation check

- Remote pellet feed with pellet length check

- Presses with 90 tons clamp force

- Capability for clear compound

- Unwanted object detection in the press to prevent damage

- Remaining cull detection when molded products are unloaded

- Large cull bin, can be emptied while the machine continues production

- Flexmode operation (cleaning while production continues)

- Clean room class 1000

- Machine is CE compliant

- User friendly touch screen

- Machine manuals available on the user interface

Specifications

Machine Dimensions

| Width | 2 press system: 3,733 mm 3 press system: 4,173 mm |

|---|---|

| Depth | 1,759 mm |

| Height | 2,150mm |

| Weight | 2 press system: approx. 4,290 kg 3 press system: approx. 4,935 kg |

Leadframe Dimensions

| Width | Max. 75 mm |

|---|---|

| Length | Max. 280 mm |

Cassette Dimensions

| Width | 85 mm |

|---|---|

| Length | 300 mm |

| Height | 165 mm |

| Storage capacity | 800 mm |

Supply Requirements

| Voltage | 208-230-380-400-440-460-480VAC - 3~ |

|---|---|

| Frequency | 50 / 60 Hz |

| Power rating | 8.5 - 13 kVA |

| Compressed air | 5 - 10 bar |

| Average air consumption | 6 m3/h at 6 bar |

| Factory exhaust | 500 m3/h at 50 Hz |

Press and Mold Properties

| Max. clamp force | 900 kN |

|---|---|

| Max. mold opening | 124 mm |

| Max. transfer pressure | 120 bar |

| Pellet diameter | 14 or 14.3 mm |

| Max. number of plungers | 10 |

| Max. cavity temperature difference | ± 2 ºC |

Options

- Molding Quality Inspection (MQI) - full product quality inspection

- Product size measurement

- Incomplete fill check

- Infeed inspection (identification, orientation, 2D-dot code)

- Anti jump loading

- SECS-GEM

- Anti warpage unit

- Two step loading

- Adaptive clamping

- Cavity and board vacuum

- Process monitoring with FTPC

- Bottom leadframe detection

- Mold surface scanning

- Double leadframe detection

- Remaining cull detection degater

- Adjustable clamp up speed

- Product quality inspection

- Single stack and slotted offloading

- Automatic leadframe loading during cleaning

Downloads

PDF - 2 MB