Esec 2100 SSI

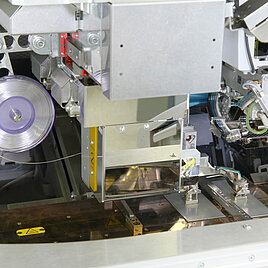

The Esec 2100 SSI is the latest addition to the proven Esec 2100 12-inch die bonder family, integrating the innovative Phi-Y Pick & Place concept with a new Soft Solder Indexer. This flexible indexer accommodates a wide range of leadframes, while the advanced Dispensing and Pre-pressing System delivers optimal performance for processing Soft Solder in today’s demanding High-Power Packages.

With a high-force, closed-loop 300N option, this platform stands out as the most versatile and capable die bonder for Diffusion Soldering and Direct Sintering on various leadframes. Its exceptional process control and productivity set a new industry standard.

Besi’s patented Soft Solder Process Technologies, combined with the Esec 2100 SSI, help maintain a competitive edge in the market.

Demonstrations and sample builds with your material can be done on a live machine in one of our labs. We are happy to invite you for a visit. Contact us today for more information.

Key Features

Leading Edge Machine Concept

- Dedicated Real-time OS for tight process control

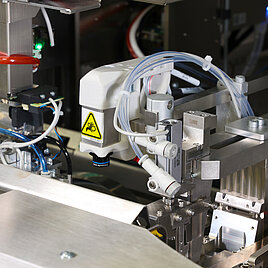

- High performance P&P and Dispensing Technology

- Constant status control with real-time wafer, strip and magazine viewers

- Real-time process monitoring through live images of the Pick and Bond process zone

Best Process Quality

- Lowest gas consumption

- Patented dispensing and bonding technology.

- Closed-loop bond force control and auto force referencing (300N option).

- Process visualization and display of bond force curve during process setup (300N option).

Widest Application Range

- Handling of strips up to 300 x 102 mm

- Process Down Holders with up to 75N force

- Smart Push-In (SPI) and Smart Push-Out (SPO)

- Convenient application and strip data import via product kit dongle

Fastest Time to Yield

- Recipe transfer from machine to machine enables fast conversion

- Supports Soft Solder, High Force Diffusion and Direct Sintering processes

- Assisted Teach/Setup workflows and teach parameter verification to eliminate setup errors

- Enhanced application flexibility and exchange of product-specific parts for fastest product changeovers.

Leading Edge Process Control

- Advanced atmosphere control

- 4 programmable gas flow zones

- Air cooling and vacuum flow monitoring

- 8 programmable heater zones

- Accurate and flexible temperature profile settings

Specifications

Accuracy / Productivity

- 50 μm / 0.8° @ 3σ (Soft Solder)

- 35 μm / 0.5° @ 3σ (Eutectic / Diffusion)

- Dry cycle: 265 ms

- MTBF: > 200 h

Process

- Bond force: 0.2 - 50 N (300 N optional)

- Bond rotation: 360°

- 4 programmable gas flow zones

- 8 programmable heating zones

Leadframe Size

- Width: 15 - 102 mm (max. 4”)

- Length: 90 - 300 mm

- Thickness: 0.1 - 2.0 mm

- Downset: max. 2.5 mm

Wafer and Die Dimensions

- Wafer size: 4” - 12”

- Frame size: 8” - 12”

- Die size: 0.5 - 15 mm

- Die thickness: > 0.075 mm

Soft Solder Indexer (SSIN)

- Handling of strips up to 300 x 102 mm

- Process Down Holders with up to 75 N force

Supply Requirements

- Voltage: 208 - 240 VAC 1P / 3P Delta (@ 47-63 Hz)

- Voltage: 360 - 415 VAC 3P Wye (@ 47-63 Hz)

- Power rating: typical 3000 VA, max. 10500 VA

- Compressed air: min. 5.2 bar

- Vacuum: min. -0.75 bar

- Forming gas: min. 2.2 bar

Machine Dimensions

- Footprint: W x D x H: 2500 x 1448 x 1400 mm

- Weight: approx. 1650 kg

Options

Input Handler

- Magazine Handler Input (MHIN2)

Substrate Handler

- Power Marking Unit (PMU)

- Process DownHolder P1 (PDP1)

Pick & Place

- High Force 300N Option

Die Ejector – Process Modules

- Dual Stage Die Ejector

Vision

- Strip Vision Input (SVI)

- Strip Reader QR (SVIQR)

Automation

- Wafer Mapping inclusive Conversion

- Host Communication Interface

- E142 Strip Mapping (SMP)

- Transfer Logging (TLOG)

- Material Tracking (MTR)

Dual Dispense Solder

- Pre Press Head System 1 (PPHS1)

- Wire Dispense Head System 2 (WDHS2)

Miscellaneous

- Uninterruptible Power Supply to PC (UPS)

- Ionizer-Controlled Pick (IONC-P)

- Ionizer-Controlled WH Load Top (IONC-WT)

- Ionizer-Controlled Magazine Input (IONC-MHIN)