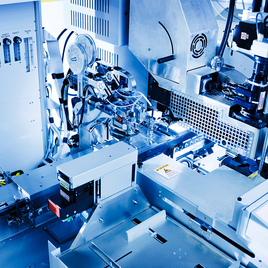

Esec 2009 SSIE

The new Esec Die Bonder 2009 SSIE is engineered to meet all upcoming challenges in power die attach. Its unprecedented productivity and process control are unmatched in the industry. Thanks to the patented soft solder process technologies the Esec Die Bonder 2009 SSIE ensures your leading market position.

The 2009 SSIE is the only softsolder bonder in the market able to handle 300mm / 12" wafers (optional).

Key Features

Highest Speed

- New point to line pick & place

- High speed high accuracy dispensing technology

Best Process Quality

- Lowest gas consumption

- Patented dispensing and bonding technology

- Process visualization

Widest Application Range

- Solution to handle the ultra thin and ultra wide leadframes

- Solution to process power modules

Fastest Time to Yield

- Fast product change over with exchangeable indexer

- User friendly menu structure

- Easy to use mechanical design

Co-Development

- Involve in power package design

- Work closely together with customers and suppliers

Ready for the Future

- Expandable machine design

- Multi process capability

- Ultra thin die handling

Specifications

| Net productivity | 2,500 to 8,000 UPH typical |

|---|---|

| Typical bonding accuracy (product dependent) | 60µm @ 3σ with optical bond centering option: 50µm @ 3σ |

| Solder wire spools | Diameter: max. 155 mm / 6.1” Width: max. 12 mm / 0.47” Mounting hole: 8 mm to 10.5 mm / 0.31” to 0.41” |

| Wafer size | Up to 8" 12" optional |

| Die size | 1 x 1 mm to 11 x 11 mm 40 x 40 mils to 430 x 430 mils |

| Machine dimensions | 1,970 x 1,305 x 1,760 mm (W x D x H) |

Options

Handling

- Magazine Handler Input

- Magazine Handler Output

- Top Stack Loader Wide

- Dual Input Handler

- Dual Power Leadframe Loader

- Dual Power Leadframe Loader 2

- Stack Power

- Power Marker Unit

- Single Wafer Loader

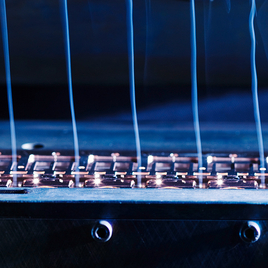

Dispenser

- Programmable Dual Wire Dispenser

- Programmable Pre Press Module

Vision

- Prog. Quality Control Television

- Optical Bond Centering (OBC)

- Pre-bond Vision Inspection (Pre-IQC)

- Post-bond Vision Inspection (Post-IQC)

Miscellaneous Options / Special Applications

- Advanced Thin Die

- Thin Die Pick-up

- Thin Die Pick-up Flexible

- Small Die Kit / Ultra Small Die Kit

- Leadframe Identification

- Uninterruptible Power Supply

- Heated Pepper Pot

- Gas Supply Feature

- Wafer Mapping Package (WMP4, incl. conversion package)

- Host Package

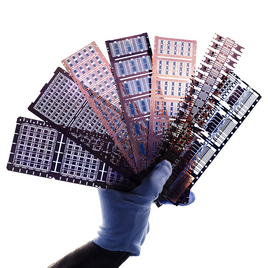

Strip Mapping

Strip Mapping E142 on Esec 2009 SSIE soft Solder Die Bonder

Get ready for the next level of ink-less production and full traceability in Soft Solder die bonding. Power packages are getting more and more complex, denser, smaller and quality critical. Strip Mapping E142 applies a virtual map-like representation of the physical world to a lot of common substrate such as e.g. wafers, leadframes and DCBs.

Key features:

Strip Identification

- Able to read 1D barcodes and 2D DataMatrix codes of various formats and sizes

- Preferred StripID location: near leading or trailing edge

Strip Mapping E142

- SEMI E142 compliant strip mapping format

- E142.2 SECS II compliant communication

- Configurable strip map download and upload settings

- TransferMap generation configurable (die level traceability)

- Wafer mapping via Stream12 still available

Benefits:

Strip Identification

- Only small StripID code area required (DMC)

- Barcode sometimes more practicable and easier to attach

- No mechanical contact with code area

Strip Mapping E142

- Well known and active standard

- SECS II based communication, easily integrated in existing host systems

- Flexible download, upload and bin code settings

- Transfer map to link wafer position to strip position for full single device traceability

Downloads

PDF - 507 KB

PDF - 595 KB