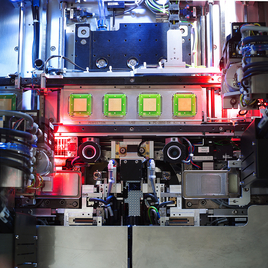

Datacon 8800 CHAMEO advanced

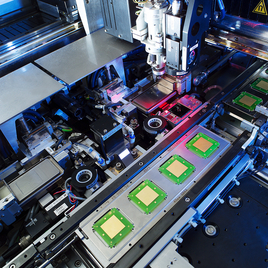

Highest Productivity for FO-WLP

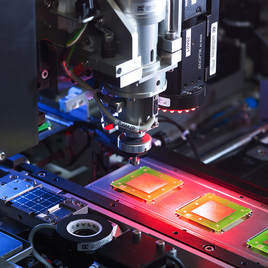

As a new advanced packaging technology, Wafer-Level Fan-Out Packaging (WL-FOP) is a cost effective solution to address increasing demands for performance, form factor, and warpage control.

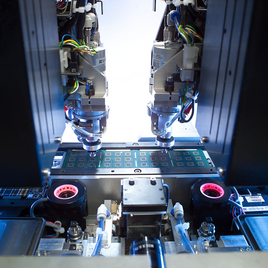

The Datacon 8800 CHAMEO advanced bonder raises a field proven platform concept to an advanced level. It is the perfect fit for chip attach of any WL-FOP process, supporting both face-down (flip mode) and face-up (non flip mode) package designs.

Key Features

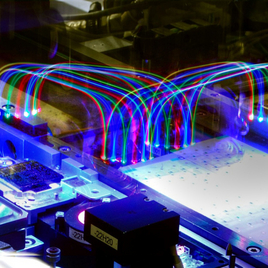

Multi-Chip – Combining Speed, Flexibility and Accuracy

- Multi-chip capability – Flexibility on smallest footprint

- Single pass is king – Improve your Cpk for multi-FC packages

- Waffle pack feeders – Extend your possibilities

- Extra Speed up to +40%

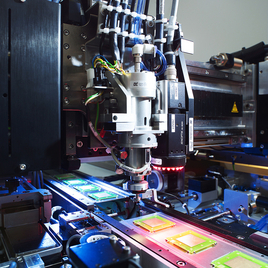

Enhanced Capabilities – Ready for the Future

- Leadframe, strip, boat, wafer – No limits for your substrates

- Customized features – Exactly tailored for your process

- 300 mm / 340 mm Fan Out Wafer Level Packages (FO-WLP) Carrier

- Face-down & Face-up (recipe controlled)

- Clean room class ISO 5

- Foup load port

- Tape & Reel

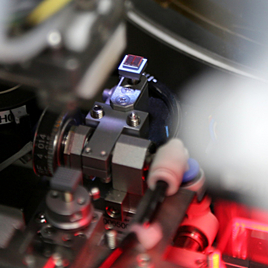

Highest Accuracy – Capturing Tomorrow’s Markets

- Highest Accuracy ± 5 µm / 3 µm @ 3 Sigma

- Local reflow – Mastering sophisticated assemblies

- Long-term stability – Securing high yield at high speed

Wafer Level Applications

- Fan-Out Wafer Level Packages – Highest performance for lowest cost

- Advanced Chip to Wafer – Cost effective dual die stacking

- Through Silicon Vias (TSV) – Entry ticket to the future

Specifications

| X/Y placement accuracy local | ± 3µm @ 3sigma (± 2µm @ 3sigma option) |

|---|---|

| X/Y placement accuracy global | ± 5µm @ 3 sigma |

| Bond force | 2 - 50N (0.5 - 10 N option) |

| Die size face down | 0.3 - 30mm (40mm option) |

| Die size face up | 2.5 - 25mm |

| Die thickness | 50µm - 3mm |

| Wafer size | 8" - 12" (on 8" or 12" wafer frames) |

| Strip, Boats, Panels | Up to 340mm |

| Substrate wafer | 12" |

| Fluxer | option, various cavity plates available |

| Multi Chip | included |

| Tap feeder option | tape size 8 - 32mm |

| Clean room class | ISO5 (option) |

| Footprint | 1,600mm x 1,200mm x 1,880mm (W x D x H) |

| Weight | 2,000kg |

| UPH | Up to 7,000 |

| Vision system | 6 x 6mm FoV for substrate and upwards camera 12 x 12mm FoV for wafer camera |

Downloads

![]() Datacon 8800 CHAMEO advanced.pdf

Datacon 8800 CHAMEO advanced.pdf

PDF - 3 MB